The Future ofGreen SteelStarts Here

Why Green Steel matters?

0

15

25

35

45

55

65

75

85

15

25

35

45

55

65

75

85

%

of input material

s recycled scrap

0

0.3

0.6

0.9

1.2

1.5

1.8

2.1

2.4

0.3

0.6

0.9

1.2

1.5

1.8

2.1

2.4

MVH

of energy saved

per batch

0

40

80

120

160

200

240

290

340

40

80

120

160

200

240

290

340

KG

of CO₂ avoided per ton

(vs. traditional steel)

At Metalfer, sustainability is built into every step of production. By using 85% recycled scrap, we reduce our dependence on raw materials and cut CO₂ emissions by up to 45% compared to traditional steelmaking. Our hot charging process alone brings energy savings of around 30%, while over 60% of our transport fleet runs on natural gas to lower our environmental footprint. And because steel is 100% recyclable — infinitely — we’re not just producing steel, we’re keeping it in motion for generations.

5-Step Green Steel Process

Our green steel journey is built around five key phases — from receiving and processing scrap to distributing the final product. Each step is designed to reduce emissions, save energy, and support a fully circular production model. Here's how we turn waste into high-quality, sustainable steel.

01

Scrap Intake

We begin by receiving and sorting scrap metal. Non-metallic materials like sponge, paper and oxide are removed to prevent unnecessary burning and emissions. Aluminium and copper are redirected into their own recycling streams - maximizing efficiency from the start.

02

Melting in the eaf

The clean scrap is melted in our Electric Arc Furnace (EAF) - a modern method that uses electricity instead of coal-based processes. This significantly lowers emissions and energy consumption, making it one of the cleanest melting methods available.

03

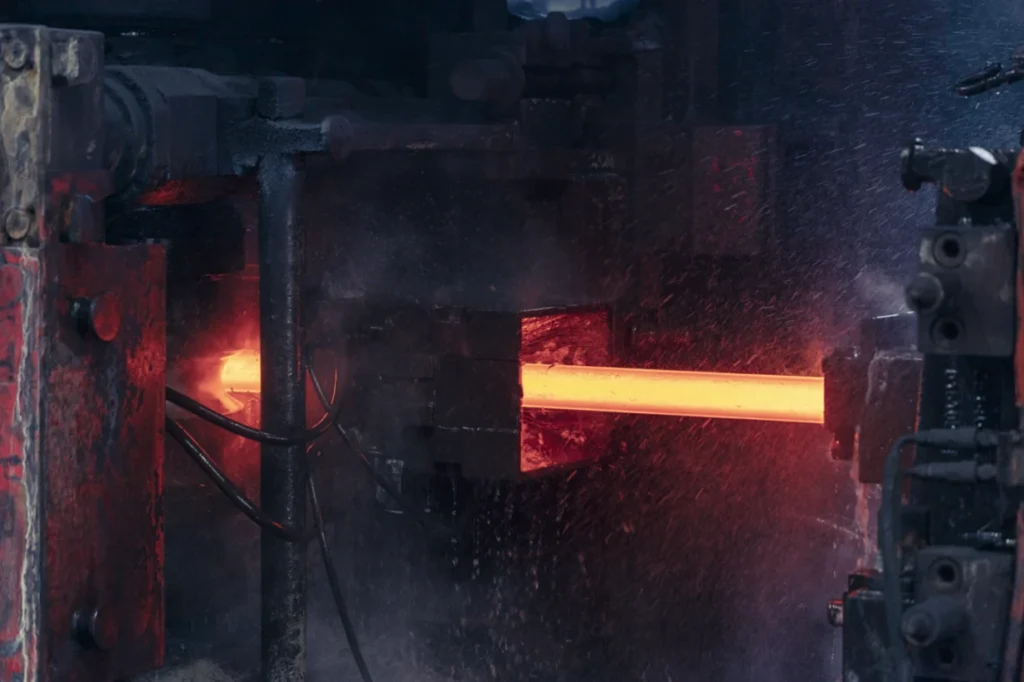

Hot Charging

Instead of cooling and reheating steel billets, we move them while still hot directly into the reheating furnace. This process, known as hot charging, saves substantial energy and shortens the production cycle, improving overall efficiency.

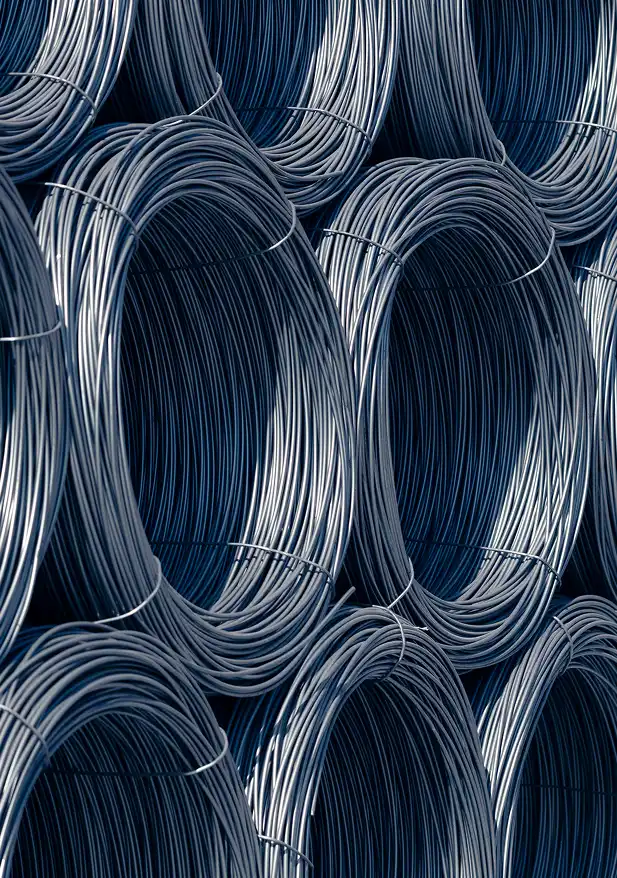

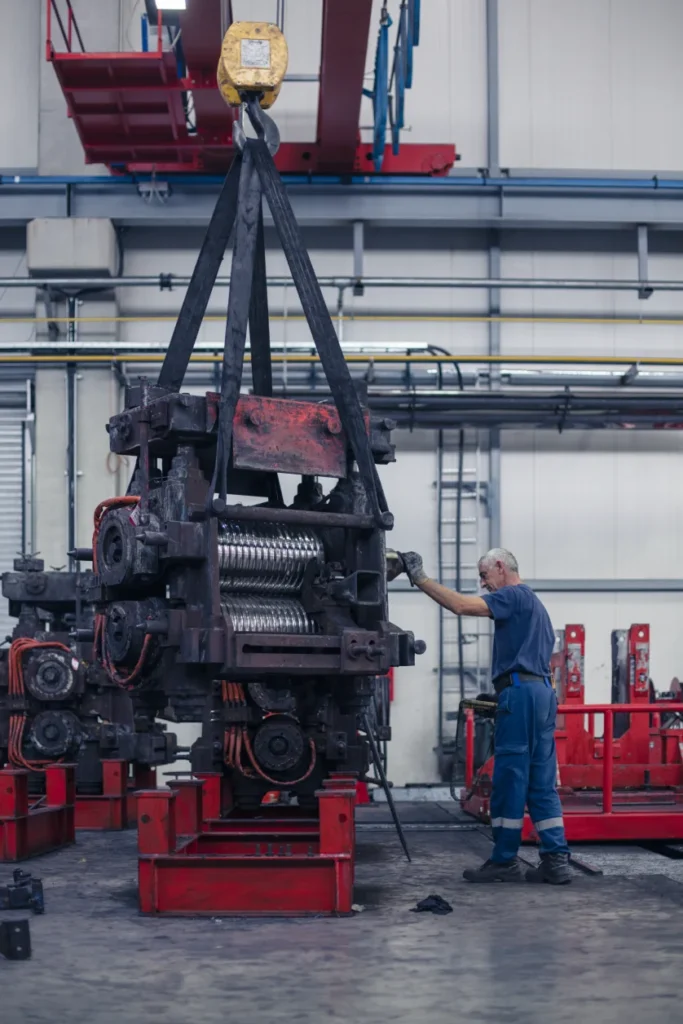

04

Rolling Mill

The billets are then shaped into their final steel forms through precise rolling. Our equipment is optimized for energy efficiency and minimal waste, helping maintain high quality while lowering our environmental footprint.

05

Transport & Distribution

Our green approach doesn’t stop at the factory. A growing part of our logistics fleet runs on natural gas, helping reduce transport-related emissions such as CO₂ and NOₓ. Sustainability continues all the way to delivery.

Steel That Never Stops Working

At Metalfer, steel doesn’t end its life — it begins a new one. Our process is designed around a circular economy model, where steel products, after years of use, return to us as scrap and re-enter the production cycle.

This not only reduces waste and conserves natural resources, but also significantly lowers environmental impact by cutting down on mining, emissions, and landfill use.

01

High-quality steel made from recycled scrap.

02

Used in construction, industry, and everyday

products.

03

Recovered after years of use, sorted and processed.

04

Melted and refined through our green

production phases.

05

Re-enters the cycle as raw material for

new steel.

Impact & Result

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.

6,200

TONS

of CO₂ emissions avoided in the past year.

92,000

TONS

of scrap processed and returned to the production cycle.

18,000

MVH

total energy saved through hot charging in 12 months.

32%

in particulate matter emissions from logistics operations.

Impact & Result

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.

6,200

TONS

of CO₂ emissions avoided in the past year.

92,000

TONS

of scrap processed and returned to the production cycle.

18,000

MVH

total energy saved through hot charging in 12 months.

32%

in particulate matter emissions from logistics operations.